8Mm Copper Rod Resistance Steel Wire Ring Butt Welder Welding

Machine

Product Introduction:

A butt welding machine is a welding equipment that uses the

resistance between the contact surfaces of two workpieces to melt

and fuse metal through low voltage and high current. Welding

machines, also known as current welding machines or resistance

welding machines, are widely used in fields such as construction

engineering and electronic products. Its working principle is to

instantly pass low voltage and high current, causing the contact

surfaces of two metals that are connected to each other to

instantly heat up, melt, and fuse, thereby achieving welding.

Features:

1. Pneumatic or hydraulic pressurization is used: with high

clamping force, it does not slip during forging and welding of the

workpiece, and the welding performance is stable.

2. Dual guide rail guidance: anti-wear, smooth and stable movement,

high alignment of workpiece interfaces.

3. Top forging mechanism: Adopting a paint mixed top forging

mechanism, it works smoothly, has high top forging force, and high

efficiency.

4. Mold electrode: Chromium zirconium copper, excellent material,

not afraid of high temperature wear, good conductivity.

Main Application areas:

1. Welding of handles for various kitchen utensils such as knives,

forks, spoons, shovels, and scissors;

2. Welding of bicycle, motorcycle, car rims, and other metal rings;

3. Welding of various metal wires, metal strips, iron bars, and

construction steel bars;

4. Various round and square tubes are welded in an "L" and "T"

shape;

5. Diagonal welding between window frame and door frame;

Technical Parameters:

| Item/Model | | DN-40 | DN-63 | D(T)N-80 | D(T)N-100 | D(T)N-125 | D(T)N-160 | D(T)N-200 |

| Rated power At 50% | KVA | 40 | 63 | 80 | 100 | 125 | 160 | 200 |

| Rated primary power | V | 380 | 380 | 380 | 380 | 380 | 380 | 380 |

| Secondary Voltage | V | 5.2 | 6.7 | 7.9 | 8.3 | 8.6 | 9.1 | 10.6 |

| Rated frequency | HZ | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 | 50/60 |

| Max.Short Circuit Current | KA | 14 | 15 | 16 | 18 | 20 | 28 | 34 |

| Max. weld power | KVA | 62 | 86 | 170 | 280 | 300 | 330 | 410 |

| Throat | MM | 500 | 500 | 630 | 630 | 630 | 630 | 630 |

| Max.Froce at electrodes | N | 6000 | 6000 | 10000 | 10000 | 10000 | 12000 | 12000 |

| Working stroke | MM | 20 | 20 | 30 | 40 | 40 | 50 | 50 |

| Cooling Water Consumpion 2.5bar | L/min | 6 | 6 | 8 | 8 | 8 | 10 | 10 |

| Electrodes tlp | MM | Φ13*45 | Φ13*45 | Φ16*45 | Φ16*45 | Φ16*45 | Φ20*45 | Φ20*45 |

| Arms | MM | Φ50*150 | Φ50*150 | Φ80*220 | Φ80*220 | Φ80*220 | Φ80*220 | Φ80*220 |

| Projection Clamping Plate | MM | 125*125 | 125*125 | 200*200 | 200*200 | 200*200 | 200*200 | 200*200 |

Max.Welding Capaciry A3 steel | MM | 2.5+2.5 | 3+3 | 4+4 | 4.5+4.5 | 5+5 | 5+5 | 6+6 |

Detailed Images:

Stable Pressure Application

The direct pressure integrated pressure application mechanism has

good follow-up and does not slip during workpiece welding, with

stable speed.

Easy To Operate

Using a microcomputer controller, it can analyze, adjust and

control the welding process parameters of the welding machine, and

the operation is

simple.

Copper Alloy Electrode

Made of high-quality materials such as chromium zirconium copper,

it has good conductivity and can be used with confidence.

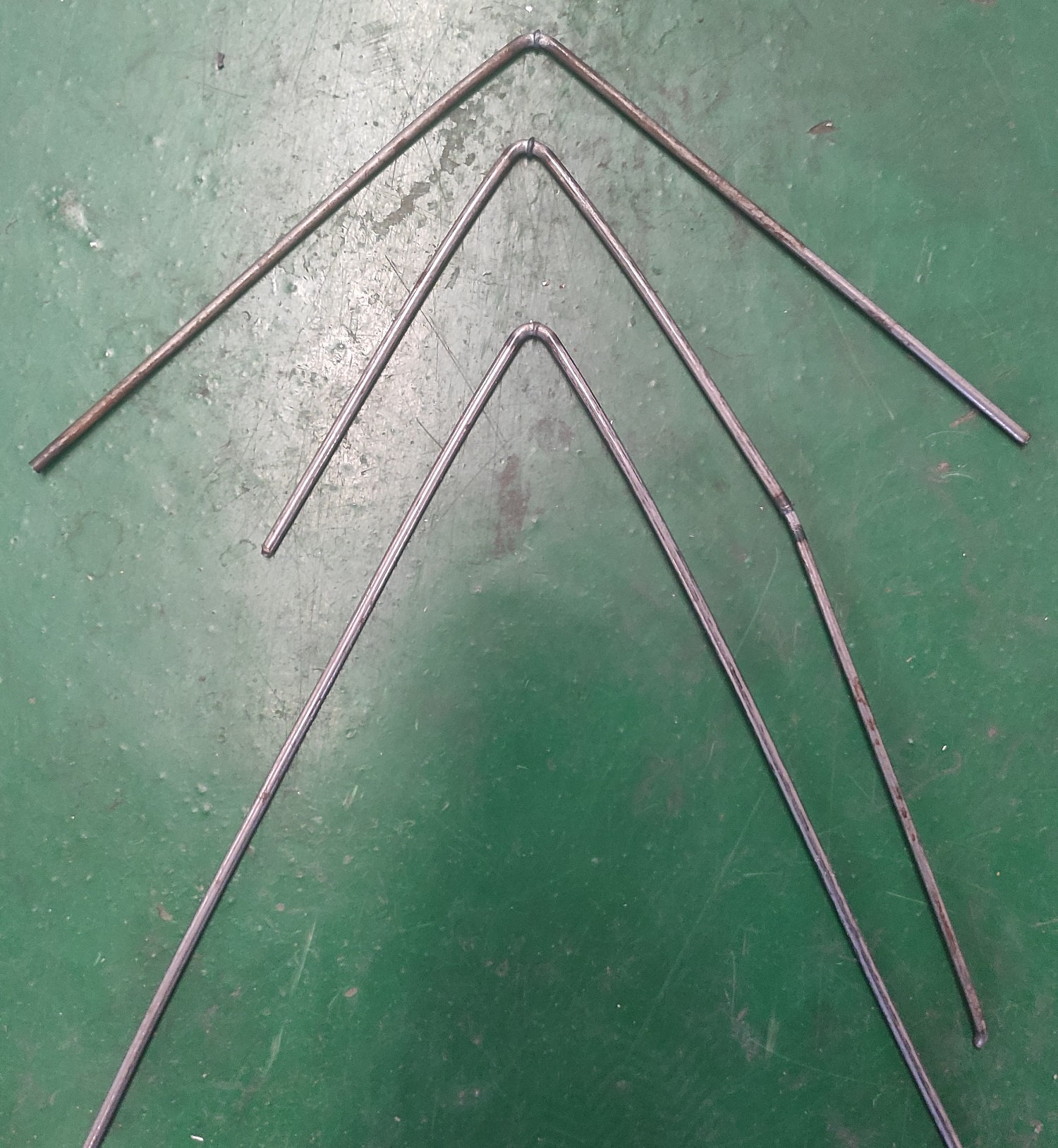

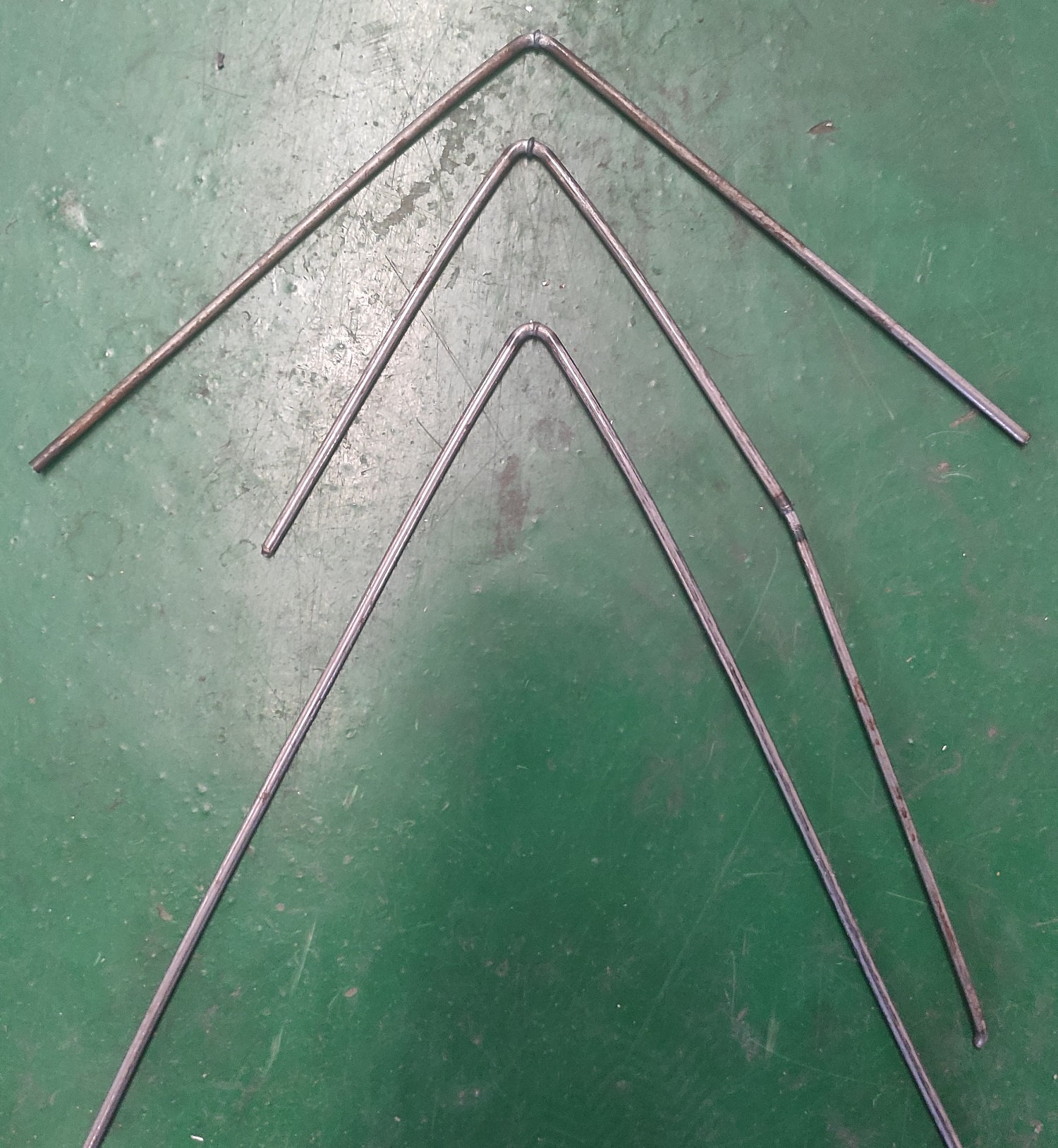

Scence Images:

Application:

FAQ:

1. When can you arrange shippment?

The shippment is 15 days after getting deopsit, but customized

machines should be more than 25 days.

2.Do you inspect the finished products?

Yes, each step of production products will be came out inspection

by QC department before shipping.

3.Are you factory?

Yes, we are factory, all machine is made by ourself and we can

provide customize service according to your requirement.

4.How to buy your Spot Welder?

Please send us inquiry to our email, and we will give you a PI to

send us payment.

5. How to contact you?

You can send a mail for us and call us.

6.How will you deliver my goods to me?

We always ship by air and sea in the mean time.

7.How about your transport packing? Is it possible to damage the

machine during the transportation?

We have rich experience on international transportation. All the

packing are extra thickness carton filling with protective PE foam

and waterproof membrane. No damage happened during transportation

until now.

8.What kind of payment do you accept?

T/T, Western Union, PayPal, .L/C, D/A, etc.

Company Profile: